The purpose of this Method statement is to explain the erection and installation of Agitator for tanks and vessels in Phosphoric acid plant or any chemical production facility.

Function of the agitator is to maintain homogeneity in the fluid by creating turbulence.

Generally Agitator consists of a big size shaft with a blade which is installed vertically over the tanks, and it will be coupled to a motor through a gearbox.

This method statement covers installation of agitator over the tank and erection, alignment, coupling of gearbox with motor.

Erection of blades is done by bolting/welding.

The method is applicable for the following items:

FILTER CAKE WASH TANK AGITATOR

FILTARATION SUMP AGITATOR

CONCENTRATION SUMP AGITATOR

FLOURINE SCRUBBER – SEAL TANK AGITATOR

ACID SUMP AGITATOR

WEAK ACID MATURATION TANK AGITATOR

WEAK ACID STORAGE TANK AGITATOR

WEAK ACID SUMP AGITATOR

CONCENTRATED ACID MATURATION TANK AGITATOR

CONCENTRATED ACID STORAGE SUMP AGITATOR

POST PRECIPITATE SLUDGE SUMP AGITATOR

EFFLUENT TANK AGITATOR

WASHING STATION SUMP AGITATOR

FLOUSILICIC ACID STORAGE SUMP AGITATOR

Related / Referenced Documents

Vendor’s manual for installation of agitator

Release certificate for the agitator support structure

Release certificate for the tank

AFC Drawings

Inspection and Test Plan ITP

Health Safety and Environmental

All the persons involved in this activity will be with proper PPEs.

Proper scaffolding will be provided if working at height more than 1.5 meter.

TOOL BOX talk will be conducted daily at the starting of activities.

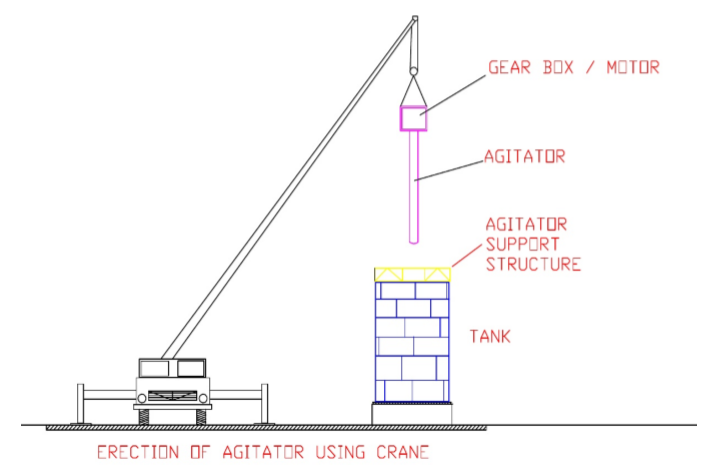

Proper crane selection for erection purpose with 70-80% efficiency.

Proper disposal of Oil/grease waste after applying lubrication.

All the lifting tools are certified.

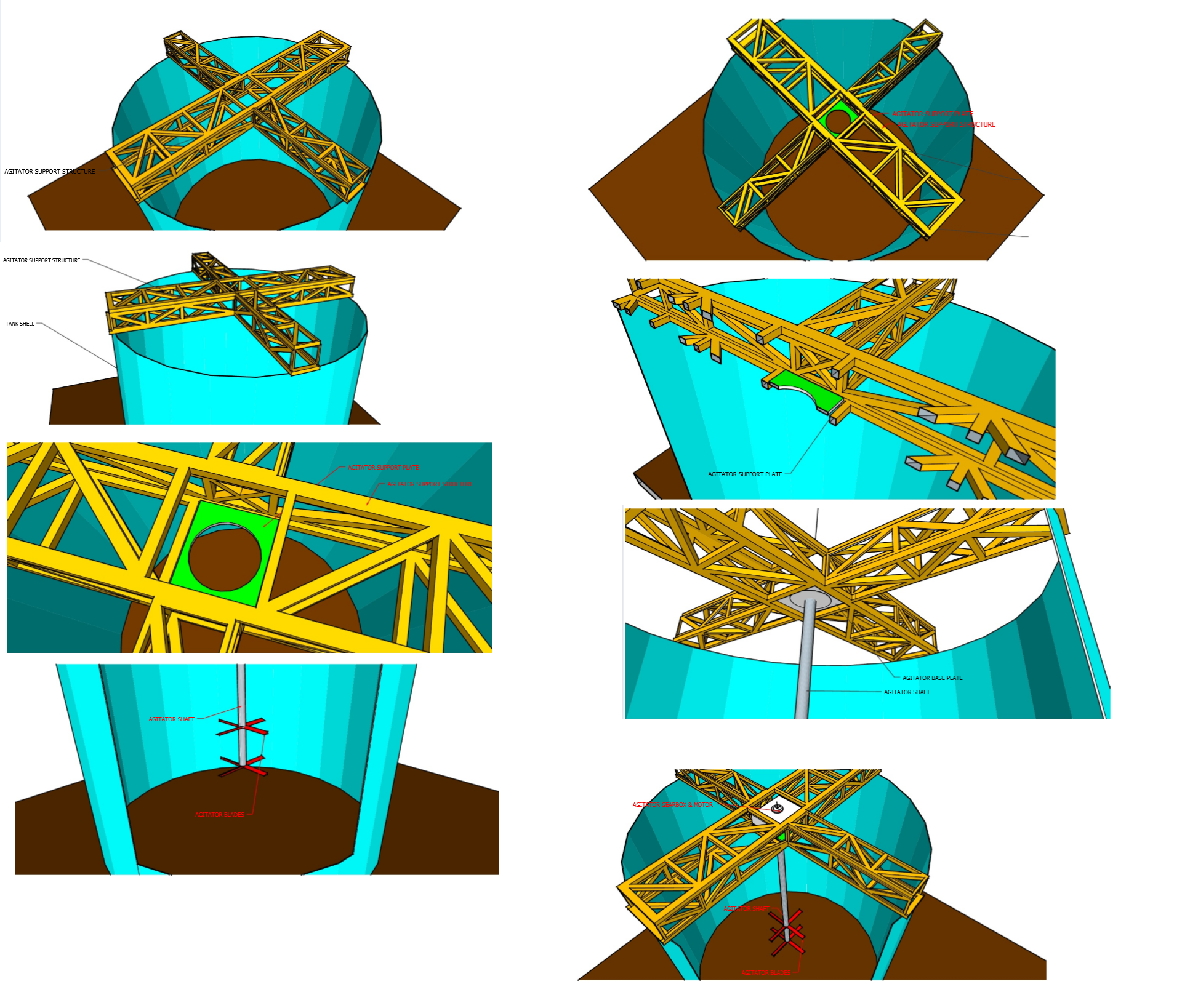

Detail of work supported with sketches and with special highlight for details

1. Erection and welding of Agitator support Plate.

2. Inspection of welding / joints.

3. Preparation of Agitator shaft for erection.

4. Alignment and coupling of gear box to the Agitator shaft.

5. Surface preparation of Agitator support plate i.e. grinding, finishing etc.

6. Positioning of Agitator shaft near to the tank.

7. Positioning of crane for erection purpose.

8. Erection of Agitator shaft over the support plate.

9. Tightening of bolts.

10. Installation of anti vibration elements if applicable

11. Checking the verticality of the shaft.

12. Tightening of the bolts to the required torque.

13. Check for free rotation of shaft.

14. Check the verticality of the shaft.

15. Erection of Motor and coupling with the gear box.

16. Alignment of motor with gear box.

17. Check the free rotation of shaft.

18. Erection of scaffolding inside the tank.

19. Erection and bolting of Agitator Blades to the shaft (WLEDED / BOLTED TO BE COFIRMED).

20. Alignment of Blades

21. Bolt tightening to the required torque.

22. Electrical and instrumentation cabling.

23. Check for the direction of rotation.

24. Grease and lubrication applications

25. Release for commissioning.

Curing and Weather Protection

The motor gear box may be covered properly for to protect from dust and moisture.

Show hold points for internal and external required inspection including specified tests on products.

Construction Equipment to be used , including standby Arrangement

Mobile crane for erection purpose and arcane with equivalent or more capacity crane are available at site.

Lifting equipment, involved (where applicable, crash, tower crane…test and location).

Manpower involved and Trades, who does what and when

Supervisor for Tanks: He monitors all the activities associated in erection and installation of Agitator.

Riggers: These will involve in handling the plates for erection, alignment etc.

Millwright Fitter: He takes the fit up of nozzles and other pipe supports and structural items.

Welders: will do all the welding operations.

Grinders: will do grinding operation for the tank.

Helpers: are the general helpers to skilled workers involving in job.

Crane operator: will operate the crane.

QA/QC Team: will guide the job for required QA/QC levels.

Work Schedule Requirements’ and Timing for This work.

For this job the daily regular work hours will be 10 hrs. excluding lunch time.

From 7-00Am to 6-00PM. 3.

On weekly half’s required core skilled workers like welders will be engaged if necessary.

Training and Orientation for the Team

For all the team members TOOL BOX TALK will be conducted at the beginning of activity on daily basis.

The scaffolding team will be trained and certified.

Crane operator will be trained and certified.

The riggers involved will be trained and certified.

Regular monitoring of welders is required and if necessary training will be given regularly.

Tests on Systems (QA /QC )

Checking the verticality of the agitator shaft.

Check the alignment of Agitator base plate.

Check the alignment of the coupling as per required tolerances.

Tightening the Nuts and Bolts with the proper torque.

Logistics involved if work is expected to extend beyond normal working hours.

Lighting while working at night.

Shade protection while the wind velocity is very high.